Big update, I spent the entirety of the last weekend working on this, and I can now say that the exhaust leak I was experiencing is now completely fixed.

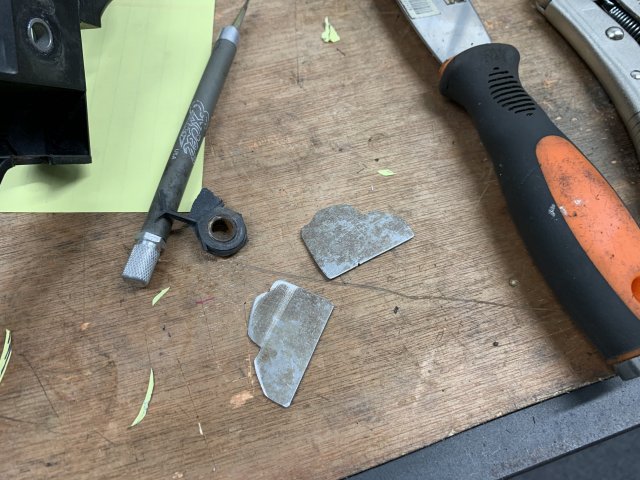

As a refresher, I suspected that there was a leak at the level of the exhaust manifold. The broken stud pictured here was the first clue.

I wanted to have the most space possible because I knew I had to extract the broken stud. So out went the subframe assy.

Here is the absolute horrible job the local shop did trying to fix the leak. They butchered my work, and I was incredibly angry at this situation for a good month after finding out. I got a refund at the end, but yeah.

After a couple of hours later, I liberated the engine of it's manifold and turbo. We can clearly see the right-most exhaust port covered in soot.

It's at this point I realized I had two studs broken in the block. Oh boy... You can also clearly see the soot where the leak was.

I was really lucky to have the help of my father. He worked on drilling and extracting the studs on the block and later on the turbo manifold. He even made a drilling guide adapter that slotted into the block to drill square into the studs.

While he was working on this, I started to jig up the exhaust.

After another hour, I transferred the flange off of my old exhaust to the newer one the shop chopped up.

I also had to jig up the exhaust hanger because I had to cut much lower that I thought because the shop inserted the flex pipe a good 1.5in into the ID of the OEM exhaust.

You can see my small welds. I essentially tacked-welded the entire circumference of the pipe. I could not do continual welds because I was burning through the material. The metal was thinner because of corrosion.

At last, my dad managed to get one stud out completely. The other one he could not, he was forced to tap the hole with the old metal still in there. We could not take the chance to torque the extractor more, fearing having a hardened steel part stuck into the head. That would have been much more horrible.

After cleaning both the mating surfaces of the block and the manifold, I installed a new gasket, new studs where needed and all new nuts.

I torqued at around 70-80% the torque value for the stud that we re-tapped. I did not have confidence in a full torque going by the feel of it.

I also broke every single bolt off of the manifold side of the turbo, all three...

Which naturally led to my father helping me drill through and re-taping the threads.

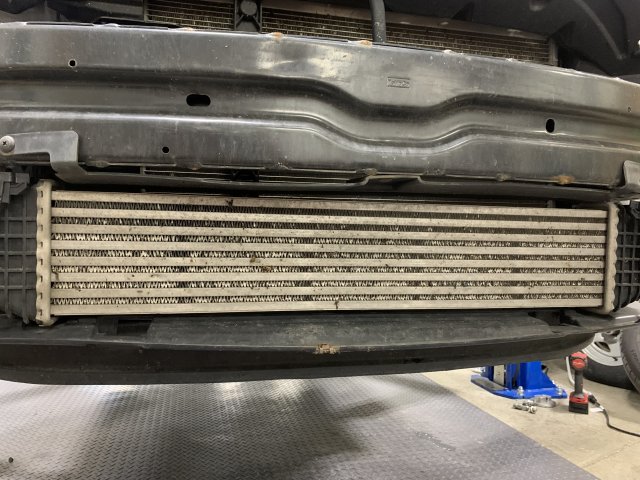

Just before all of this, I installed a DV+ and inspected the turbo. I wished I had a new oil feed line, the old was a bit crusty. I did have a new bolt for it, though.

I installed the turbo back on with new coolant lines and a new oil return line. Torqued all the nuts to spec as well.

Downpipe installed, RMM back on with pretty much all the pipes. And yes, I did not forget the hose clamp on the turbo inlet.

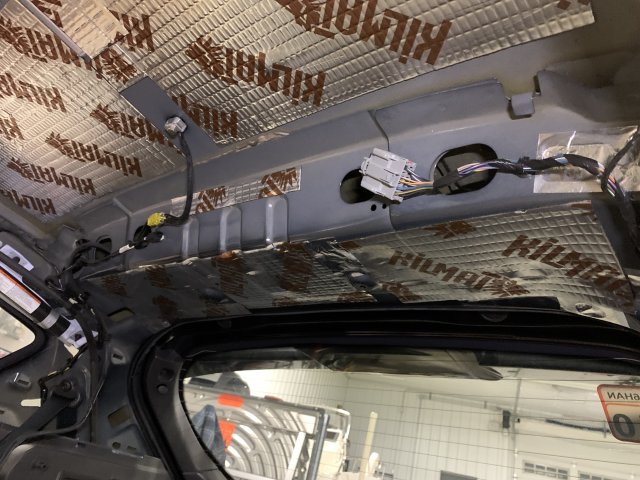

I also copied the

@Dialcaliper design for the crossover tube. Even used pyrogel. The only thing different is that I ordered the 10 mm thickness. It's not the final version, I covered the exposed section where you see the insulation at the level of the bracket.

Subframe back on, with the new down pipe, newly welded hanger and flange. My jig fixture was 1/4in off in the rotation axis, so the bottom of the resonator is not perfectly parallel to the ground. It's very close to OEM, though.

Overall, I'm very happy about the result. The first start after doing all of this was uneventful, which was the desired outcome. I also primed the oil into the turbo before starting up the engine.

Quiet as before, smoother than before as well. I worked two 14h days on this, while taking my time, but working through all the problems one by one. I'm thankful for my father's help because the car would still be on the lift without him.

The car smoked for a good 20–30 minutes after it's first start. It seemed to be coming from the manifold area. The smoke was white and close to odorless. It did not smell like oil burning, but closer to coolant burn-off. After the initial smoke, the engine is since smoke free.

Next post will be about the suspension refresh I did (before the exhaust work).

![Frown [:(] [:(]](/images/smilies/frown.png)

![Mad [mad] [mad]](/images/smilies/mad.png) ), this is the front brace I will install as well.

), this is the front brace I will install as well. ![Thumbs Up [thumb] [thumb]](/images/smilies/icon_smile_thumb.gif)

![Frown [:(] [:(]](/images/smilies/frown.png)

![Mad [mad] [mad]](/images/smilies/mad.png) ), this is the front brace I will install as well.

), this is the front brace I will install as well.