Along side all these other things, Yes I am like a squirrel and work on a half dozen things at a time, been looking into some rear beam locating collars. My beam and Woods247 beam have shifted a couple of times on track and while I know why mine did, (its in the avatar pic), Matt's probably did it under normal track usage. I ask one of the Bspec prep shops if they had seen the issue and they hadn't. Oh well, on with my own path.

The OE bolts are a stupid design. Must have been cheap for Ford to make them this way, but damn its a dumb way to lock something down that needs to stay in place.

Notice how the shank on this bolt is smaller than the threads. The hole in the body and the whole in the beam mounting points are 33% larger than the bolt shank. WTF Ford. How hard would it have been to make the shank larger and thus get the subframe located better? Pretty sure the front bolts do a much better job of this. Ford did a nice job with the washer, I think they are trying to rely on the friction created by the washer to keep things from sliding. Probably more than fine in normal operation, but not bouncing over curbs at RA and Barber.

This is just a regular grade 12mm 8.8 bolt I had laying around. Notice how the shank has a much larger diameter than the threads. This is beneficial in that it gives more bearing area for my locking collars to push against and it makes the bolt stronger. I am gonna order some grade 10.9s (equivalent to OE hardware) and change all of the OE bolts when I finish the collars.

I noticed someone on the Fecebook group is making them, but they made theirs out of aluminum. I don't need to tell you why that is a poor choice of materials in this case. The sample I made up this evening is 303 stainless. Its plenty strong enough and will resists corrosion better.

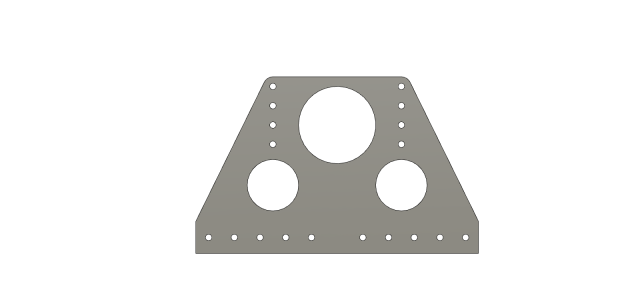

I am debating whether I need all three holes to have these or if I only need them on two holes per side. Theoretically once the bolts and collars are tightened into place, all of the holes may not allow for collars to line up correctly. Will have to check that as I get into it. I may find that not all of the bolt holes in the beam mounts line up enough to put the collars in all of the holes, but having the collars in will work better than the current arrangement.

![Frown [:(] [:(]](/images/smilies/frown.png)