Installed my FSWERK exhaust today. I started by getting the car up on jackstands. I wanted to get the car up as high as possible. I have two 2 ton Craftmans jacks and two 3 ton Craftmans jack stands and two hydraulic jacks, one is a heavy duty Craftmans jack and the other is Harbor Freight low profile jack. To get the car 18" off the ground, requires jacking the car up with both jacks. Each jack stand has the capability of supporting the ST at the pinch points without touching the pinch points.

The reason I supported the rear at the jack points (the pinch points behind little doors) was to let the rear tires droop. This made getting the old muffler out easier.

There are only two fasteners holding the exhaust in place. There are four elastomer hangers that hold up the exhaust. The FSWERKS installation instructions recommend spraying the hangers and the fasteners at the down pipe with a penetrating oil, one hour after the engine has cooled. I used PBblaster. Even after a one hour soak, the two fasteners were really hard to move. They are 15mm nuts. I ended up having to take a harbor freight ratcheting breaker bar, with a 15mm six point long socket, and push on the ratchet with my foot to break those suckers loose. Then there are the rubber hangers. I used a combination of PBBlaster, a large channel lock, and a small phillips head screw driver to pop them loose.

FSWERKS provides two replacement fasteners and washers for the downpipe nuts, which is really thoughtful of them. The OEM ones got slightly rounded, so I was glad I didn't need to get replacements. The next step, per the instructions was to pull the cross brace off the underside of the body, but I left it in place.

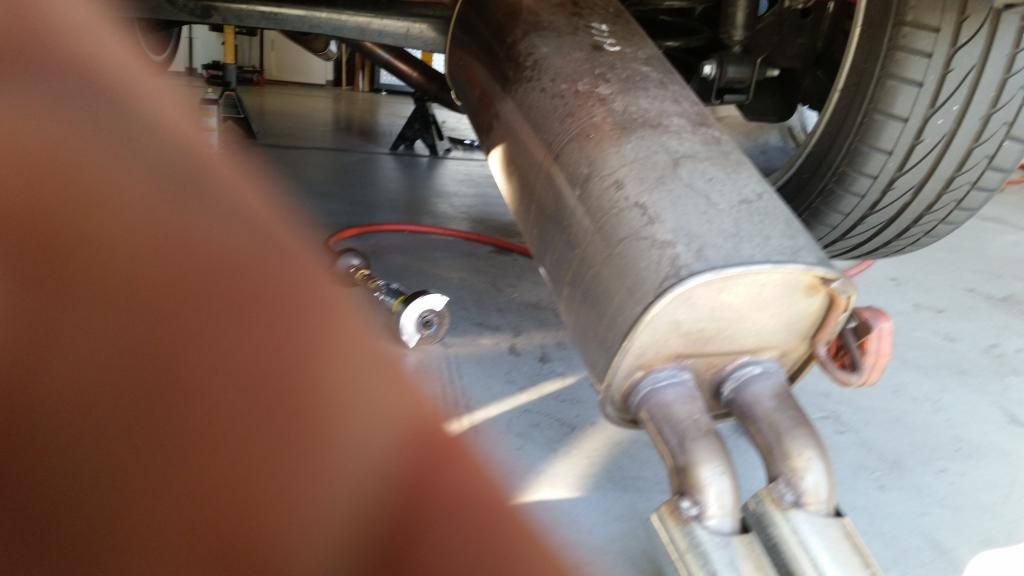

I then took a small air grinder to cut the exhaust into two pieces.

After the cut, I removed the cross brace, and dropped the front of the exhaust out of the car.

Putting the FSWERKS exhaust in was so much easier, I was able to use my 3/8" air ratchet to attach the mid pipe. I used silicone grease to grease all the exhaust hangers. This made everything slide right into place. An adjustment of the midipipe on the hangers to center it underneath the body was really easy with the silicone grease. I inserted the pipe which goes over the rear brace, along with a hard clamp.

The muffler was a little difficult to get into the proper place, I used the Harbor Freight jack and a couple of small pieces of 2 x 4s to hoist it up to where it needed to sit, then connected it to the bent pipe, along with anither hard clamp. All clamps were loose at this time.

I intalled the twin exhaust tip, and added a shop rag to locate the tips so that they didn't touch the opening and be centered.

Then I tightened the clamp that joins the bent pipe to the muffler, then the clamp that connects the mid pipe to the bent pipe. I removed the rag, and then tightened the light duty clamp.

After that, I pulled my rear wheels, touched up my rear calipers with red duplicolor caliper spray paint. I cleaned my wheels, both sides, and sprayed them with outlast wheel protector, and then put them back on. I dropped the car and changed my clothes and went for a little spin. Sounds great. I'll post before and after videos tomorrow.