I don’t know what to do now…

TL;DR - camber bolts won’t fit - one is now jammed and a part of it is potentially broken. Am following the official instructions.

Powerflex camber bolt install started 3 hours ago. Read the instructions (loosen bottom strut bolt, align washer and bolt, fit into strut tower). I had trouble getting the bolt to fit through the strict tower holes and control arm holes, washer or not. Even with a mallet I was only able to get the eccentric lobe halfway into the control arm hole before it wouldn’t budge.

I resorted to tapping the bolt in with a mallet as far as it would go and then using the nut on the other end to tweak it down and try to pull it through using brute force from the threads. I already, maybe, messed up one side by doing this too far and the washer is jammed in a wrong position - which from other forums seems to be a sign to toss this one. With the other washer I was much more careful and didn’t mess this up again, but the small tab on this washer doesn’t fit into the strut tower hole nicely. I could keep trying to screw the damn thing in, but I’m worried that either the washer, or worse, my strut tower hole, will be damaged.

Advice would be appreciated. I have given up for the day and am clueless as to how this would be so difficult.

Picture gallery (and instructions attached):

The side that’s completely jammed - washer in an incorrect position. Afraid the washer tab is broken, or would be dangerous to drive on.

The other side, where the washer hasn’t been crushed yet, but no matter which way I rotate it (either right or wrong as per the instructions), it won’t fit nicely into the strut tower hole.

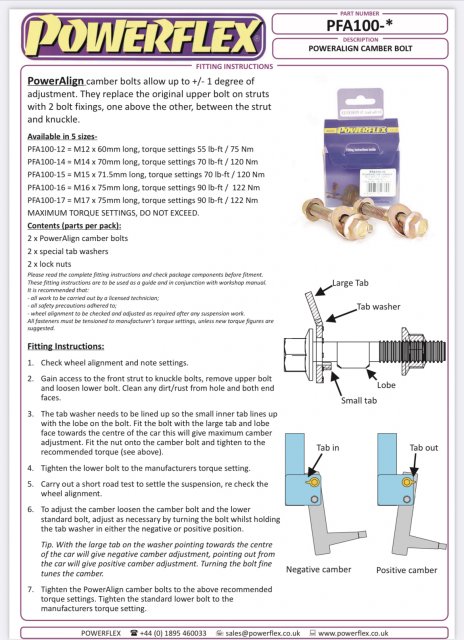

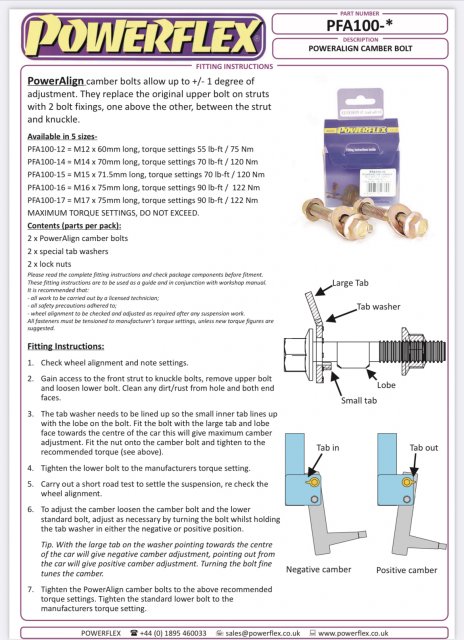

Powerflex Camber Bolt Instructions:

TL;DR - camber bolts won’t fit - one is now jammed and a part of it is potentially broken. Am following the official instructions.

Powerflex camber bolt install started 3 hours ago. Read the instructions (loosen bottom strut bolt, align washer and bolt, fit into strut tower). I had trouble getting the bolt to fit through the strict tower holes and control arm holes, washer or not. Even with a mallet I was only able to get the eccentric lobe halfway into the control arm hole before it wouldn’t budge.

I resorted to tapping the bolt in with a mallet as far as it would go and then using the nut on the other end to tweak it down and try to pull it through using brute force from the threads. I already, maybe, messed up one side by doing this too far and the washer is jammed in a wrong position - which from other forums seems to be a sign to toss this one. With the other washer I was much more careful and didn’t mess this up again, but the small tab on this washer doesn’t fit into the strut tower hole nicely. I could keep trying to screw the damn thing in, but I’m worried that either the washer, or worse, my strut tower hole, will be damaged.

Advice would be appreciated. I have given up for the day and am clueless as to how this would be so difficult.

Picture gallery (and instructions attached):

The side that’s completely jammed - washer in an incorrect position. Afraid the washer tab is broken, or would be dangerous to drive on.

The other side, where the washer hasn’t been crushed yet, but no matter which way I rotate it (either right or wrong as per the instructions), it won’t fit nicely into the strut tower hole.

Powerflex Camber Bolt Instructions: