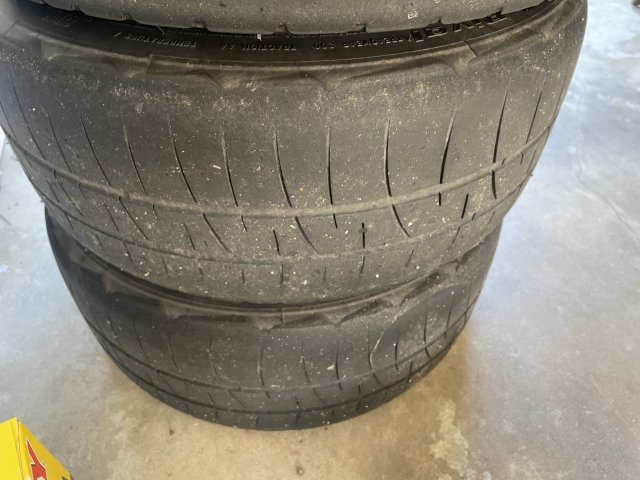

More fun experiments. After looking at the corner weights, decided to play with some Speedthane spring rubbers I was able to borrow to stiffen up the left side and see if frequency matching makes a difference. The difference at stock springs rates is pretty negligible, but with increased spring rates, it appears that to match right and left frequency on the same axle, it’s actually a step stiffer on the left rear (+25lb), and a bit less on the Left front (+15lb).

The weight difference isn’t large, and obviously it will change with passengers in the car, but this is an experiment. The spring rubbers come in assorted stiffnesses for tuning. Values are really approximate (and change depending on how many winds the installed spring has), but “nominally” they are something like 5,10,15 and 20 and 50lb increments. In reality they are just rated by durometer and at high compression are progressive, but the rates are low enough to not matter and just like bumpstops of the same material, they are initially fairy linear. Race teams that want to really dial them in will run the actual spring with different rubbers installed on a spring tester to check the actual rates that result.

Already using 2 of the “20lb” rubbers in the rear to get “close” a 224(4k) spring on the 200lb springs I have. Went a little conservative and added a “10lb” to the left front, and a “15lb” in the left rear which should get closer to balanced frequency.

The car has had a very “busy” rocking side to side wobble going over bumps. I had just chalked it up to one-wheel bumps combined with the stiffer sway bars.

It might just be my imagination, but I feel like it might have improved slightly.

The theory would be that if the left/right sides have significantly different natural frequency, after a bump, which is an input, the suspension will oscillate until damped by the shocks. This is why there’s a “bounce” after any road feature - you’re not feeling 100% of the road feature, just a small jolt reduced by the suspension, followed by a “settling” bounce

This is why natural frequency is important - because a car never tracks the road features perfectly. That would require zero stiffness springs, massless unsprung wheels and/or an infinte mass vehicle

One theory is that when one corner of the car is heavier, the two sides may get “out of sync” which may show up as a side to side wobble - much like the “pitching” front to back you get from a suspension with overly stiff front springs because the rear that hits the bump later never catches up.

Alternately, it could be that the spring rubbers are providing some slight extra compression damping. Either way, it seemingly helped.

The nice thing about the rubbers is that you can in theory install and remove them without unbolting anything, or even removing the wheels. You just need to jack up the car so the suspension can droop. (They can be a bit tight going in)

![Wink [wink] [wink]](/images/smilies/wink.gif) )

)