I'm new here and to Turbo 3 and 4 cyl. motors. Ask Mr. Clarke what internal guts makes their transmission so much superior to the FORD OEM with a LSD. Is it the Metallurgy they use in the gears? is it the clutch material? the # of splines on the output shaft? Helical cut gears? Magnesium for lighter weight and stronger gears? COOLING?

Since you are running a track car HARD EVERY DAY that you are on the track, I don't think u are what FORD Engineers had in mind with the BEAN COUNTERS controlling cost on an Entry Level Street/Sport Tuned car.

Please let us know what Colby Clarke has to say. We are all living vicariously through ur track adventures.

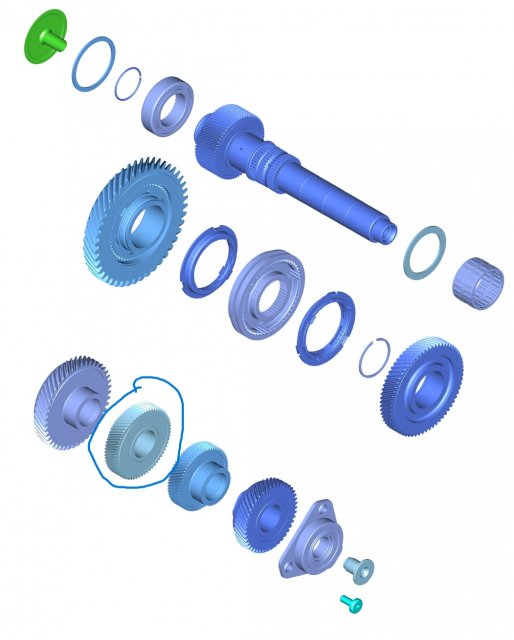

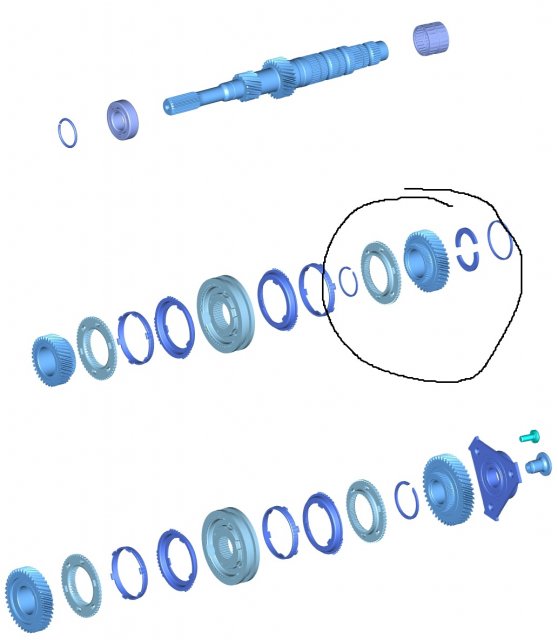

Back from Mitsubishi/DSM days, the things I’m aware that make a custom rebuilt transmission better than the stock one are down to a few things, a lot of which come from seeing where customer transmissions have failed.

- Biggest difference in longevity is the care of a builder that meticulously adjusts and reshims gear backlash to the tight end of the service spec, sometimes tighter if they find it works on higher powered cars with thicker lubricants. The biggest transmission and diff long term killer is loose backlash, followed by too-tight backlash.

- Second difference is identifying the weakest points in the transmission through experience, and if possible, adjusting clearances, making small modifications, or replacing things like OEM bearings and bushings and other wear parts with higher quality ones (often from bearing suppliers like SKF, Torrington, etc)

- Lastly sometimes swapping out with parts from other similar transmissions from different car models (and makes). Ours is a Getrag supplied gearbox like a lot of other OEMs use (not just Ford), and occasionally other similar but beefed up parts are used elsewhere in other Getrags. I don’t know if any builders that handle our boxes have really experimented that much, as it’s not a common transmission, and most motorsports applications that use IB6’s either use them stock, convert to dog boxes or replace them with sequentials. Cars that see a lot of drag racing rebuilds and subsequent explosions (DSMs, Hondas, etc) will have accumulated more of these bits of knowledge.

Besides shot-peening and cryotreating, some builders have experimented with micropolishing gears and sometimes coatings (moly, tungsten disulfide/Microblue or DLC), but none of those come cheap.