I liked the whoosh map adapter better than the one that came with my turbosmart kit

-

Sign Up! To view all forums and unlock additional cool features

Welcome to the #1 Fiesta ST Forum and Fiesta ST community dedicated to Fiesta ST owners and enthusiasts. Register for an account, it's free and it's easy, so don't hesitate to join the Fiesta ST Forum today!

Turbo Technics S280

- Thread starter ROCKYFiestta

- Start date

I had to mess with the oil return from the bottom of the turbo a few times to stop it from doing the same thing. I ended up swapping from an OEM gasket there to a crappy gray one you can get from ATP and it fixed the issue immediately. No clue why.

I noticed some dried residue that looked like oil as well. No oil drips though. I did have coolant leaking from the freeze plugs on the turbo itself. Had to unbolt the turbo off the manifold to get enough room to get a 1/4 ratchet in there.

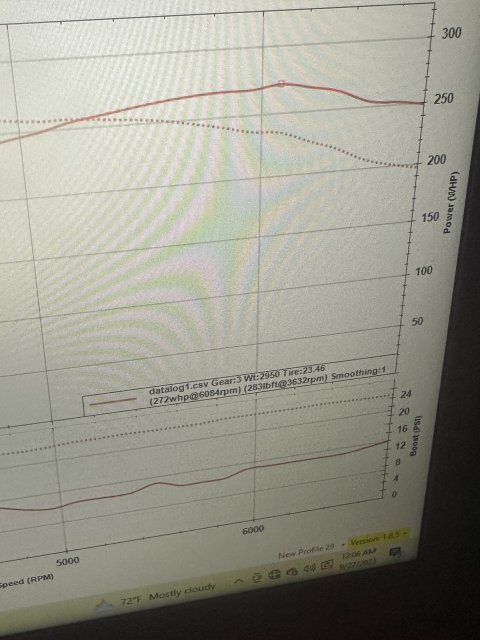

Definitely loving this turbo. I don’t get crazy wheel spin in second and it gets decent traction with the current tires I have on. I’m in my second revision with Adam on 91 and this is where it’s at. I think it’s about time to wrap up 91 and couldn’t be happier. Completely left a FRS in the dust earlier after he tried to play with me lol. I was just cruising and he wanted the beans lol

Attachments

-

1.6 MB Views: 39

Hey Guys who installed this turbo themselves:

Which coolant line gets routed where? Is the top line the supply which connects to the battery side and the bottom line connect to the passenger side? Anybody know?

Edit: Figured it out

Top=passenger

Bottom=driver

Which coolant line gets routed where? Is the top line the supply which connects to the battery side and the bottom line connect to the passenger side? Anybody know?

Edit: Figured it out

Top=passenger

Bottom=driver

Why is it difficult to find flow for these turbo’s? I want to know mostly out of curiosity. I’m old school and used to guage turbos on known turbo’s i’ve run. Mostly Mitsu stuff like 20g’s, 16G’s, E316G’s for small frame turbos, which by today’s standards on this platform would be considered big. Won’t even mention the large frames I’ve since irrelevant to small turbos which the S280 def is IMO.

I know the 20g flowed 39 lbs/min at peak efficiency, but on track days I’ve run it full closed wastegate and saw 40psi dropping to 28 by redline. Def not recommended, but always kept spares. For us old heads, what would this turbo compare to. 16g? Super60? Have to be over 40 to probably know anything about those turbos. Lol. Thanks for anyone in the know.

I know the 20g flowed 39 lbs/min at peak efficiency, but on track days I’ve run it full closed wastegate and saw 40psi dropping to 28 by redline. Def not recommended, but always kept spares. For us old heads, what would this turbo compare to. 16g? Super60? Have to be over 40 to probably know anything about those turbos. Lol. Thanks for anyone in the know.

Aftermarket turbos have all gone to custom designed billet compressor wheels, which while they are designed with industry knowledge and CFD simulations around a few potential operating points, they are not tested like the production turbos are.

But to put some things in context, almost all bolt on Fiesta ST turbos (Whoosh, S280, Pumaspeed, etc) are designed around a Borg Warner (KKK) K04 turbine wheel, the next frame size up from the KP39. The K04 is 44/50mm diameter - slightly smaller even than a T25/28 or TD04 turbine wheel (about halfway between a T22 and T25. Much smaller than any TD05H turbine you’d find on a 16G. The compressor sizes vary much more in size, but the turbine wheel ultimately is limiting exhaust flow.

You can tell some, but not as much information about the compressor wheel diameter, keeping in mind that like in the DSM world, you can get a bit more out of a billet wheel. The S280 is basically designed around a Disco Potato (GT2860RS) compressor housing (but with a better flowing wheel). A standard potato is good for 300-360hp combined with the standard (larger) GT28 turbine, so with a billet wheel and smaller turbine, the S280 comes out in about the same ballpark.

Long story short, even the biggest big turbos we strap to these cars are smaller than the 56mm turbine and 68mm compressor on a “Big/E3” 16G, but that’s pretty normal considering we’re dealing with a smaller 1.6L engine, and a stock standard cast wheel E3/16G can hit 350hp on pump and well over 400 on E85/race gas on a 2.0L engine.

Just remember that wheel diameters put you in the ballpark, but are really broad strokes when it comes to actual flow, especially since various wheels are designed for both different pressure and flow operating points.

The main advantage of billet wheels is not so much that they inherently flow more than cast wheels - it’s more that you can tweak the blade design to move the most efficient operating points (efficiency island) to higher pressure and flow points than the original compressors were designed for.

Last edited:

This ^ is the best explanation I've read so far and makes it way easier for me to understand coming from the old school MHI world. Crazy the performance gained from a turbo about the size of a T2Small (T25) that was on the 2G Eclipse/Talon. A 14b could flow 405cfm. Guessing the S280 is close to 450-500.

Anyway, I got the 3.5 bar MAP adapter from Dizzy. Do I need to connect the turbo to it or do I have to plug it off because I am not using any BOV besides the whoosh spacer. Sorry if someone already mentioned it in here somewhere.

How do you know how fast you are going when the speedometer max out in Mexico?

How do you know how fast you are going when the speedometer max out in Mexico?

Anyway, I got the 3.5 bar MAP adapter from Dizzy. Do I need to connect the turbo to it or do I have to plug it off because I am not using any BOV besides the whoosh spacer. Sorry if someone already mentioned it in here somewhere.

How do you know how fast you are going when the speedometer max out in Mexico?

How do you know how fast you are going when the speedometer max out in Mexico?

Finalized my tuning with Jason, he's saying I'm making a good 50whp over stock. While I'm fairly happy with that number, on first glance 200-220whp (depending on measuring variables) on 92 feels a little low. Not that I distrust his judgement, but more just trying to figure out my own expectations. I know inevitably I'll want to upgrade something again and I only try to make changes with proven gains since anything else is a waste of money unless it makes me feel good, and he indicated that switching from stock intake wouldn't do me much. Which was a surprise seeing other people's experiences, but if it's good enough then it's good enough.

This only came up because now I'm sort of through the honeymoon phase and I'm doubting myself having put in all this effort for something that the butt dyno doesn't feel like it's faster (in spite of knowing it is objectively faster). I don't know. I don't regret it, but I think my expectations were set too high even compared to other people on pump gas. I can pick up E85/race fuel/whatever but it's not common at the pumps here so I'll be paying $$$ if I want it for the track.

Ultimately I'll come to terms with it regardless, but I don't want to leave easy power on the table if I can lmao

This only came up because now I'm sort of through the honeymoon phase and I'm doubting myself having put in all this effort for something that the butt dyno doesn't feel like it's faster (in spite of knowing it is objectively faster). I don't know. I don't regret it, but I think my expectations were set too high even compared to other people on pump gas. I can pick up E85/race fuel/whatever but it's not common at the pumps here so I'll be paying $$$ if I want it for the track.

Ultimately I'll come to terms with it regardless, but I don't want to leave easy power on the table if I can lmao

Finalized my tuning with Jason, he's saying I'm making a good 50whp over stock. While I'm fairly happy with that number, on first glance 200-220whp (depending on measuring variables) on 92 feels a little low. Not that I distrust his judgement, but more just trying to figure out my own expectations. I know inevitably I'll want to upgrade something again and I only try to make changes with proven gains since anything else is a waste of money unless it makes me feel good, and he indicated that switching from stock intake wouldn't do me much. Which was a surprise seeing other people's experiences, but if it's good enough then it's good enough.

This only came up because now I'm sort of through the honeymoon phase and I'm doubting myself having put in all this effort for something that the butt dyno doesn't feel like it's faster (in spite of knowing it is objectively faster). I don't know. I don't regret it, but I think my expectations were set too high even compared to other people on pump gas. I can pick up E85/race fuel/whatever but it's not common at the pumps here so I'll be paying $$$ if I want it for the track.

Ultimately I'll come to terms with it regardless, but I don't want to leave easy power on the table if I can lmao

This only came up because now I'm sort of through the honeymoon phase and I'm doubting myself having put in all this effort for something that the butt dyno doesn't feel like it's faster (in spite of knowing it is objectively faster). I don't know. I don't regret it, but I think my expectations were set too high even compared to other people on pump gas. I can pick up E85/race fuel/whatever but it's not common at the pumps here so I'll be paying $$$ if I want it for the track.

Ultimately I'll come to terms with it regardless, but I don't want to leave easy power on the table if I can lmao

E85 is overall the best bang for buck even on stock hardware. I agree with you, the gains after that aren't that great on the stock turbo. I upgraded the intercooler and crossover pipe and lost some torque and gained a little HP. I don't plan on doing anything else unless it's a turbo at this point.

I wish I had gotten it dyno'd before the S280 went in so I could put hard numbers of improvement to what I feel, but I didn't do that, so whoops

Ya his numbers sound real low for an S280 even by Dizzy’s own upgrade charts.

Luckily I've got some money coming in that is disposable to throw down for a new intake and a retune, and I could live with the power even without.

Definitely loving this turbo. I don’t get crazy wheel spin in second and it gets decent traction with the current tires I have on. I’m in my second revision with Adam on 91 and this is where it’s at. I think it’s about time to wrap up 91 and couldn’t be happier. Completely left a FRS in the dust earlier after he tried to play with me lol. I was just cruising and he wanted the beans lol

Full disclosure, I'm still on the stock airbox. ST200 or an ITG/Peron are on the list (along with crossover piping) but I'm a little surprised it's apparently so heavily choked up by the stock box. Hence the initial surprise to the misunderstanding about the intake.

Luckily I've got some money coming in that is disposable to throw down for a new intake and a retune, and I could live with the power even without.

Luckily I've got some money coming in that is disposable to throw down for a new intake and a retune, and I could live with the power even without.

Wish I made that much. 😪 235 whp on a mustang dyno, 255 est. whp for a dynojet on 91 tune. My 93 feels stronger but haven't dynoed it yet. Good numbers

Last edited:

Similar threads

-

-

-

-

-

FS 2016 - Kona Blue - Recaros - 300hp Hybrid Turbo - $11,000 - 122k Miles - Jacksonville, FL

- Started by los1131

- Replies: 6

-

-

-

-

Turbo Technics S280 Turbo Kit Dyno, Virtual Dyno, and Datalog Thread

- Started by JDG

- Replies: 374

-

Fiesta ST Turbo Technics S242 Hybrid Turbo Kit

- Started by JAM-Sport UK

- Replies: 13

Ford Community Posts

-

-

-

-

Official Fiesta ST Lap Time Thread

- Latest: DaleFredriks

-