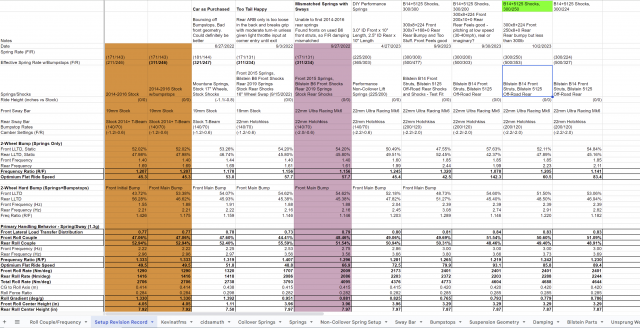

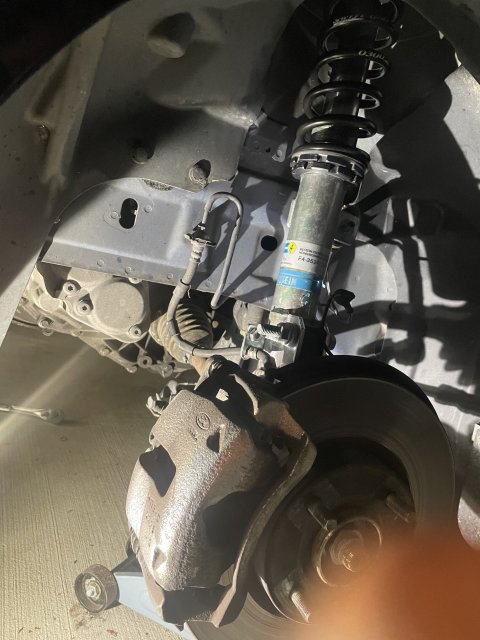

Which brings us back to Bilstein. Which while they have some shortcomings, they are high quality german monotube shocks that can be easily rebuilt/revalved, modified and still be reliable for years. So inspired by

@kevinatfms, I decided the B14 front dampers would make a good starting point. Steel body inverted monotube, which means they'll be durable and up to the task. First thing to go are the B14 springs - not the rates I want, progressive in the rear and designed for a minimum lowering of about an inch, which means not enough stroke.

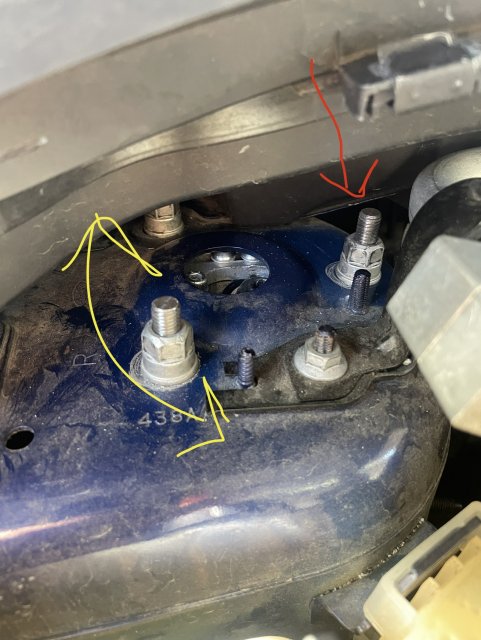

The rear B14 dampers however, are a problem. Lightly damped, and small diameter, not rebuildable. Since I'm having the shocks custom valved anyway, I can pick pretty much anything Bilstein offers as long as I can make it fit with some mild custom work. The damper I settled on is a 5125 inverted monotube. Because the stock rear dampers are mounted aft of the wheel, they have a remarkable 10" stroke! To match, the unit I ended up with is basically meant for lifted Jeeps! The steel body is a little heavy, but nice and beefy and the weight is not a problem since they're designed to be run inverted (damper is no longer unsprung weight). To accomodate the tall upper shaft, I had to drill out the center holes rear shock towers.

For now, drilled out rear top mounts are working, uniball lower joints with custom 40mm wide spacers and a custom bumpstop perch that I also made myself, which was actually the trickiest part of the whole thing. In the end, I could have just used the lower poly mounts they came with and thrown some spacer washers in there. The end result is an inverted monotube rear damper that has an additional 0.75" droop, and with a shorter bumpstop, additional compression travel as well. Important for keeping the rear wheels on the ground on bumpy roads, and ditching the stock design that engages the insanely tall (120mm) OEM bumpstop early to create a progressive spring effect.

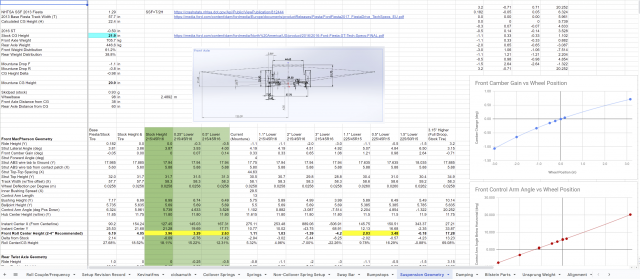

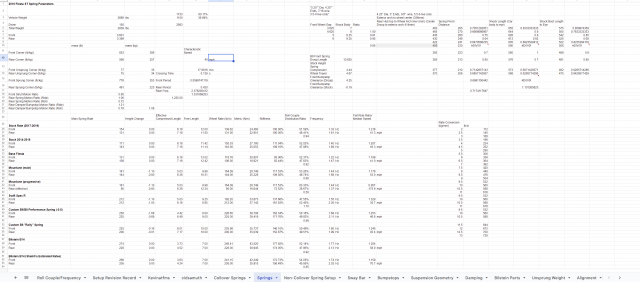

For the front dampers, I crammed on an 8" 300lb/in spring with a 224lb tender. Currently too much preload but they will be modified for additional droop when they go in for tuning and I may swap the tender out for a slightly lighter one. This lets me use as much spring length as possible with the adjusters near the lowest point so coil bind will never be an issue, and the ride height is right within that sweet spot of 0-0.5" lower than stock. The heavy tender/assist spring is tuned to give adequate preload, and a dual-rate like behavior in droop to help with shock extension on rough back roads, but will be be fully bottomed at static ride height.

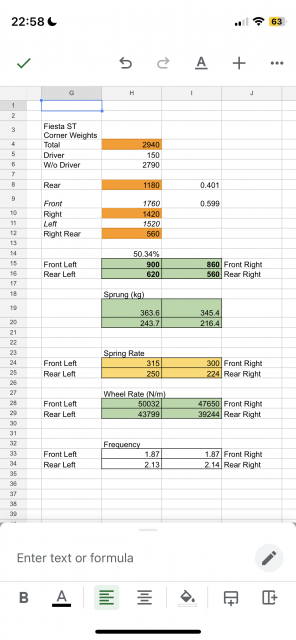

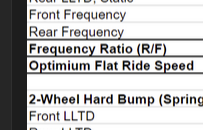

For the rear springs, I was aiming for flat ride (rear suspension frequency higher than front), and initially looking at 250-300lb/in in the rear. With 300lb springs to test, and even 250lb that I also tested, the rear ended up being way too stiff! I may have been overdoing it in order to hit an "average speed" target, I tossed my 200lb/in "rally" springs back on the rear, and while its still barely in the "flat ride" range, the road manners and stability are actually improved. I'm now thinking I'll end up in the 200-225lb range in the rear, lower than I first targeted for the rear, but surprisingly not far off the stiffnesses that both Swift and Bilstein ended up using for their kits. At first glance it looks oddly heavy in the front -

I'll be honest - the rear is different than what I had originally planned, and I was convinced I needed something much stiffer, but road testing has shown that it feels really stable without introducing any pitching or skittish behavior of the rear end on bumpy roads. Goes to show how bench racing and doing the engineering design work will get you in the right neighborhood, but only testing in reality will show all the variables.

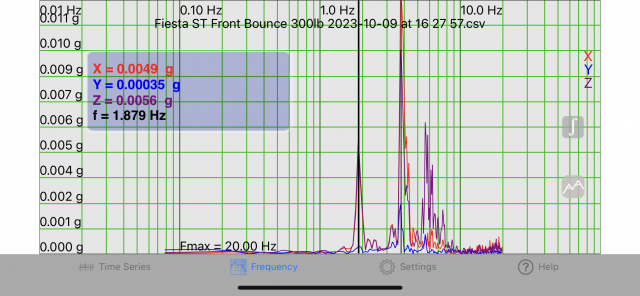

For any of those suspension nerds out there, the 300lb front springs give roughtly 1.85Hz natural frequency in the front, and 200-225 means about 2.0-2.1 Hz in the rear (so flat ride rear 8-14% higher than the front). Eventually I'll confirm with a bounce test. This is in the same ballpark as what you'll find in serious modern "factory track oriented" cars (ie, Porsche GT3). But still stiffer than what you'd find in any modern sports car (which typically run frequencies in the 1.4-1.7Hz range, which is also where our stock springs are tuned, at least for the 2014-2016 cars. The post ST200 cars are a bit softer). The 1.85/2.0Hz range is also interestingly not far off of where the "stock" car tunes in when it's jacked down on the bumpstops in a corner, and the bumpstop rate is added to the main rate.

Still plenty stiff for the track without aero, but decent backroads manners. Both from the "rule of thumb" and my experimentation, Pushing too far into the 2Hz range seems to be where "roadholding" ability starts to go to crap on anything but "nice" roads - for reference, I like smooth roads and track driving as much as anyone, but I also greatly enjoy driving the car on crappy 1-1.5 lane backroads and I want a setup that will work with both. This is basically rally car territory but with some different considerations in mind.

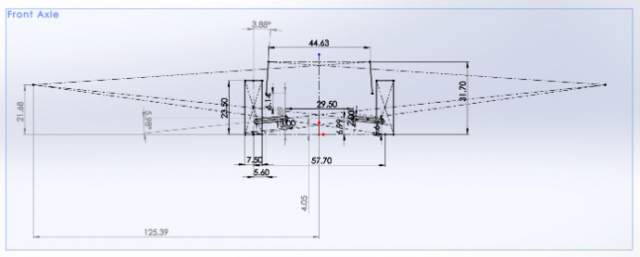

But one of the absolutely critical things that needs to happen in order to make a setup that will work on both backroads and on-track is suspension travel, which means both shock travel and using as much of the adjustment range as possible to make sure the springs won't coil bind in compression.

In the front, That means modifying the front damper internals to gain another inch of droop, and running shorter bumpstops. With the "jeep" dampers, I'll have both more droop (by about 0.75") and with the 76mm bumpstops, more compression travel looking at total of about 6" in front and >8" in rear not including the extra from tilt in the rear torsion beam, which is about as much as is practical to achieve without "lifting" the car. (This is total travel including bumpstop compression, not just damper stroke)

The rear dampers out of the box are far too overdamped in rebound (they're meant to pair with 600lb springs on lifted jeeps!), but the ride and handling aren't actually too bad as-is. Note that with the Bilstein setup, there are no "adjustment knobs" like most coilovers use. That means cracking the dampers open

After I finsh spring testing, the shocks and struts will come back off the car. Damper valving is a bit more than I want to deal with, so they'll be headed over to Fat Cat Motorsports for revalving plus some cool internal modification wizardry Shaikh over there has some up with. More to come!

![Wink [wink] [wink]](/images/smilies/wink.gif)