I have found with my valving, the car is pretty harsh on public roads even with a 250lb front spring. They have a LOT of rebound. (will get a pic of my damper curves). I have en-rounte some 162lb 8in Springs and I will swap back in the 117lb rear springs from my ST lowering spring set that hasn't sold. This well let me test a street setup. My setup is probably not the best for an average street user, especially one that drives on Michigan's bombed out roads daily.

You will have one problem, The Rear Bilsteins are probably crimped. That causes a problem for many shops. You may want to talk to your preferred shop and see if they are capable of dealing with a crimped rear shock.

What are you trying to do with the car? We already know the Bilstein doesn't have enough valving and they bandaid it with springs. I put their rear springs on my car and am not totally thrilled with the behavior. I haven't rated them, will when I get my new springs mounted. They are progressive and they block out pretty quickly which on the street makes my car too bouncy.

Preload is good. There is nothing wrong with preload.

Your ride is harsh because you're using a ton of rebound and going down on the bumpstops, not because of your main spring stiffness.

There are two "schools" of thought on suspension damping and neither is specifically "wrong" if you do it right but both have advantages and disadvantages. The stiff spring+light symmetrical damping setup is one, and it's not "old and outdated" like you've described and it actually works well for many setups. The second is what you, and most OEMs are doing with "sport models" using a lighter spring, and heavy rebound biased assymmetrical damping. The second one is designed to jack the car body down as it oscillates (basically "hunkering down to the road) until it contacts the "linear" nose of the multicellular urethane "christmas tree" foam bump stops that are pretty ubiquitous now. This creates a progressive setup that is stiffer than the spring you are using would suggest. Using a heavy rebound design means that you *must* pay attention to your actual bump travel and bumpstop spring rates, and how they add to your primary spring. OEMs use it because in straight and level driving, the softer main spring provides a more comfortable ride, and in cornering the spring aids come into play creating a stiffer setup.

@Fusion Works Are you using the OE bumpstops in the rear and the B14 internal ones in the front and have you trimmed anything? And how are you measuring your "bump travel"? If you're getting in there and measuring on the car, then yes. But if you're measuring with a jack until the wheel stops moving, then you are compressing the soft bumpstop nose until you've reached the "ramp" at the end.

For the OE front strut and spring, you can work out the bump travel pretty easily. At full droop, the front spring is compressed to just over 10.5" length, and the clearance between the 65mm bumpstop nose and strut top I measured at 4.25". Free length of the 2014-2016 spring is 12" and rate at 171 lb/in. For a stock front corner at ~850lb, that will compress the spring about 3.25" from full droop, leaving an inch clearance to the bumpstop. Going into a corner, combined with damper oscillation with rebound bias will hunker the car onto the bumpstop nose, and it won't come off until you exit the corner (which is as designed - coming back off the bumpstop is bad because it means a rate change. The rear, despite it's really long travel, acts similarly because of the aft mount (>1 motion ratio) and very tall bumpstop. I don't have a great measurement just yet

If you've lowered the car an inch (many lowering springs), then the bumpstop is basically in or very near contact with the nose just at static ride height. I don't have measurements for the internal bump travel on the B14 front (yet), but it's not going to be all that much different at a given ride height.

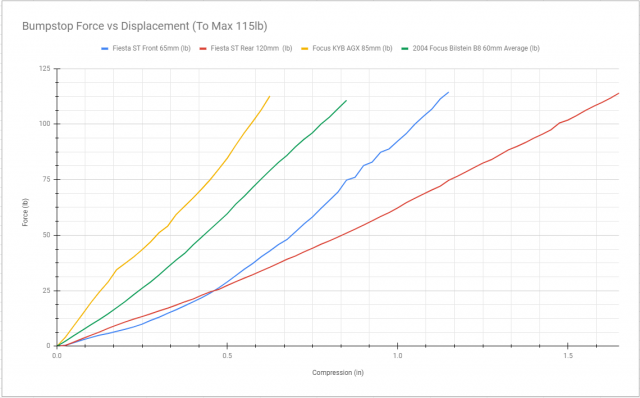

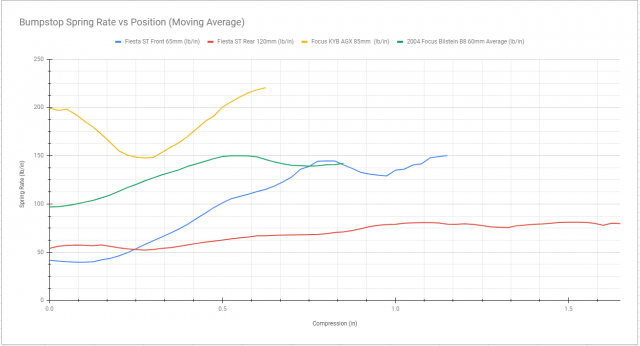

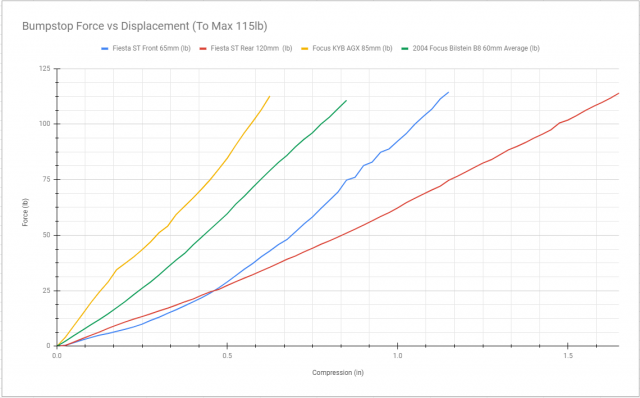

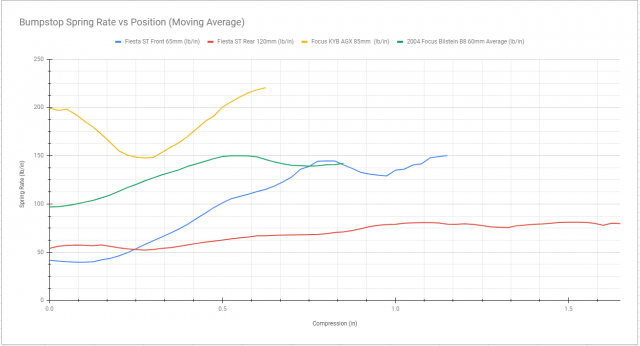

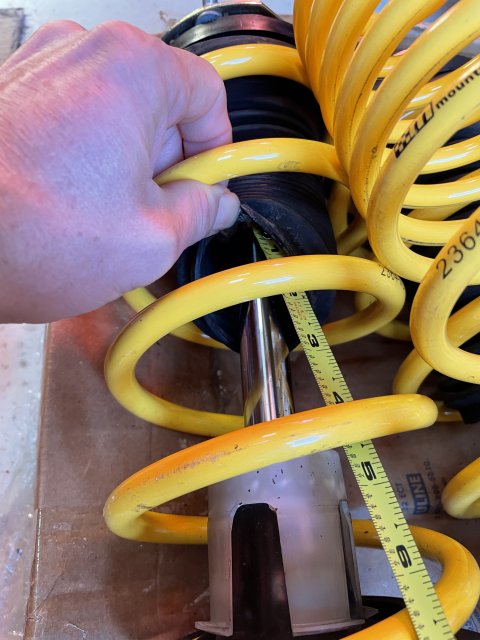

I just took some measurements on a few bumpstops kindly sent to me kevinatfms. Unfortunately I wasn't able to get ahold of the Instron at work, but I made do with a dial indicator and a shipping scale that reads up to 115lb.

You would probably get a better measurement squishing a bumpstop in the shock dyno you have access to, especially at the higher compressions where they do actually ramp dramatically

OEM MCU are 65mm front and a rather long 120mm in the rear.

The front is a progressive spring aid that has a light 40 lb/in initial rate that ramps to a "linear" section with 140 lb/in rate. I was able to measure to shy of 1.25" compression before maxing my scale, it then progressively ramps to a very high rate somewhere after that (probably at about 40-45mm compression (most MCU bumpstops will compress to about 1/3 of their initial height before going "hard"

I have confirmed this with a "bounce" test on the front suspension (at the time, I had mountune springs on OEM struts). I came up with a little over 1.4 Hz for very small motions (consistent with 181 lb/in front rate), and ~1.9 Hz for a larger displacement, which is consistent with the ~140 lb/in bumpstop engaged (for a total effective rate of about 320 lb/in in the front)

The rear 120mm (~4.75") spring aid/bumpstop has very linear behavior for at least the first 1.6" compression I was able to measure, and comes in at a rate of ~70 lb/in (slightly sloping). Because of the aft mounted damper, at the wheel where the actual rear spring is, it is effectively acting as ~100lb/in spring

This means the stock setup, in actual cornering behavior, is in reality behaving like a 310 lb/in front and ~250 lb/in rear.

The B14 internal stop is also 65mm and while I haven't measured it, the one bilstein usually uses is progressive and usually estimated as a 200 lb/in spring rate, which is how the B14 front is considered a "progressive" setup, even though the spring itself is linear (and the rear, like the Swifts, is basically using an integrated tender spring that blocks very quickly. But the B14 as it comes and as your dyno shows, does not use heavy jack-down rebound biased damping.

The B14's as delivered, with their light damping, are *not* a jack-down design, and so does not use the bumpstop as a primary spring aid. In reality, the B14 kit as delivered is a *softer* setup than the stock ST (274/228). Which makes sense because it was originally designed as a "performance" option for the base Fiesta/Mazda 2 (which are softer than the Bilstein setup)

I suspect that if you've gone with heavy rebound bias, you are turning the Bilsteins into a jack down setup, and engaging the bumpstops, which is why your 250 lb/in front springs ride horribly despite being softer than the B14's as delivered. You're engaging the front bumpstop, which could be providing as much as an additional 200 lb/in for a 450 lb/in front, which is quite stiff. You can confirm this with a bounce test (though your heavy damping will make it difficult to get an accurate result). 250 lb/in front would come in somewhere around 1.7 Hz. Adding in the bumpstop depending on where it's engaging to could put your front rate as high as 450 lb/in, which would give you ~2.25 Hz bounce, which is extremely stiff and not recommended for a non-aero car. Controlling ride height on a front splitter is really the only reason to exceed 2.0Hz front (I'm referring to a real undertray adjustable splitter, not just a fancy looking lip that you can buy from various companies). Your results will necessarily be a little off due to damping, (unless you were to actually fit the car with strut/shocks that have been drained of oil and seals removed)

I've been putting together some very in-depth geometry and suspension frequency calculations for the FiST. It's not quite ready to write up a big post on the forum (and its also a mathematical model with all it's imperfect approximations of reality), but if you're interested, send me a PM and I can share the draft with you, and if you give me some more detail on your setup and I have some spare time, I might be able to add a model in the spreadsheet for you that can give you an idea of where you are and what you're looking for a little more directly than just swapping out parts to see what works and what doesn't.

Below are my measurements of the Stock ST bumpstops up to 115 lbs (and also some Focus bumpstops kevinatfms sent me). I'd love to have measurements up to higher forces to see where the ramp starts, but I haven't had access to the proper equipment yet.