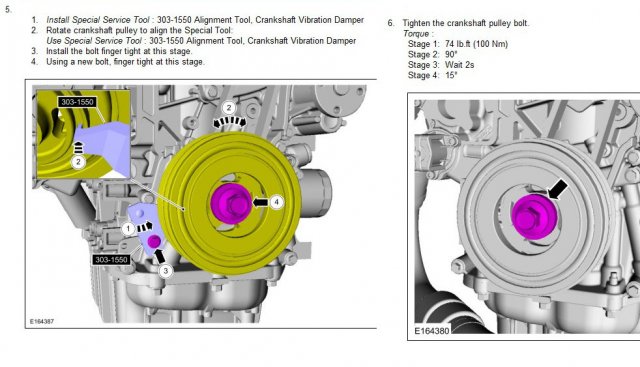

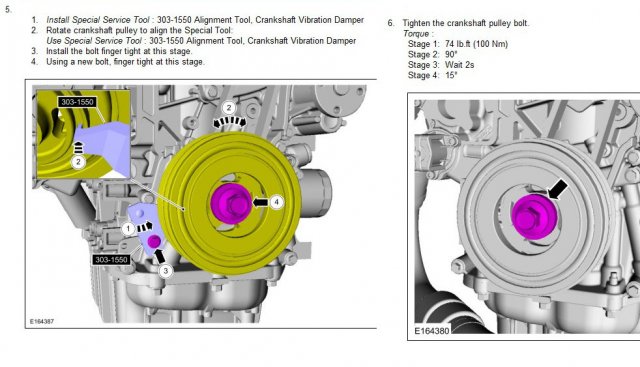

What I have difficulty with is that 90 degree rotation AFTER the initial

torque to 75 ft.lbs. Been wrenching on engines since the late 60's and most bolts would snap or strip if you tried to get an additional turn that far after setting a torque value that high. Makes me wonder if they have a Bellville Washer or something similar in the mix. If not it must be a pretty long

bolt to accommodate that much stretch. Actually in hindsight I would suspect that it may be a long bolt because by using one in this type of application you help insure that it's acting a bit like spring and wont ever come loose. It also explains why Ford specifies that a NEW

bolt be installed instead of re-using the old one.

BTW, with only 5400 miles on my FIST I don't need a new

timing belt. However I do tend to keep my cars for a long time so I am planning ahead for when a new belt is needed. After reading the procedure I expect that when that timing belt does need replacing the dealer charge will probably be pushing 1000 dollars or more. In addition all those special

tools needed to do the job won't be available for more than 10 years.