The crazy thing with LEDs is how inefficient they are in optical output. I read it’s something like 60-95% of the input energy is lost to heat. It’s not as obvious since it is not the light emitter giving off the heat (like in an incandescent bulb) it is the base semiconductor. Hence the need for enhanced cooling. They still use less total input power per lumen than incandescent (about 80% less) it’s just surprising how inefficient they are in and of themselves.

-

Sign Up! To view all forums and unlock additional cool features

Welcome to the #1 Fiesta ST Forum and Fiesta ST community dedicated to Fiesta ST owners and enthusiasts. Register for an account, it's free and it's easy, so don't hesitate to join the Fiesta ST Forum today!

Safe aftermarket LED headlight bulb info, finds and discussion

- Thread starter danbfree

- Start date

Just got the temp readings:

https://youtu.be/kDqhBepQq7g

Quick summary:

Headlight housing/bay ~150F

LED bulb heat sink ~174F

Driver ~180F

Looks like 24 deg delta between the bay and LED components. The temps did not change much from first popping the cover to the 3 plus min that I measured for. Should be fine to leave the components covered in the housing.

Quick note: The typical material used for the headlight housing is good to 300+ F and the wire insulation at least 210+F (for the cheap stuff).

https://youtu.be/kDqhBepQq7g

Quick summary:

Headlight housing/bay ~150F

LED bulb heat sink ~174F

Driver ~180F

Looks like 24 deg delta between the bay and LED components. The temps did not change much from first popping the cover to the 3 plus min that I measured for. Should be fine to leave the components covered in the housing.

Quick note: The typical material used for the headlight housing is good to 300+ F and the wire insulation at least 210+F (for the cheap stuff).

Last edited:

Just got the temp readings:

https://youtu.be/kDqhBepQq7g

Quick summary:

Headlight housing/bay ~150F

LED bulb heat sink ~174F

Driver ~180F

Looks like 24 deg delta between the bay and LED components. The temps did not change much from first popping the cover to the 3 plus min that I measured for. Should be fine to leave the components covered in the housing.

Quick note: The typical material used for the headlight housing is good to 300+ F and the wire insulation at least 210+F (for the cheap stuff).

https://youtu.be/kDqhBepQq7g

Quick summary:

Headlight housing/bay ~150F

LED bulb heat sink ~174F

Driver ~180F

Looks like 24 deg delta between the bay and LED components. The temps did not change much from first popping the cover to the 3 plus min that I measured for. Should be fine to leave the components covered in the housing.

Quick note: The typical material used for the headlight housing is good to 300+ F and the wire insulation at least 210+F (for the cheap stuff).

Thread Starter

#164

Thread Starter

#164

If its any consolation.....I have been running XENONDEPOT H11 LEDs and they utilize a aluminum ribbon and I have tucked them into the housing and closed them up....No issues to be reported or failure and its been over a year on their Gen 2 Extreme H11 LED bulbs.

Thread Starter

#165

Thread Starter

#165

Just got the temp readings:

https://youtu.be/kDqhBepQq7g

Quick summary:

Headlight housing/bay ~150F

LED bulb heat sink ~174F

Driver ~180F

Looks like 24 deg delta between the bay and LED components. The temps did not change much from first popping the cover to the 3 plus min that I measured for. Should be fine to leave the components covered in the housing.

Quick note: The typical material used for the headlight housing is good to 300+ F and the wire insulation at least 210+F (for the cheap stuff).

https://youtu.be/kDqhBepQq7g

Quick summary:

Headlight housing/bay ~150F

LED bulb heat sink ~174F

Driver ~180F

Looks like 24 deg delta between the bay and LED components. The temps did not change much from first popping the cover to the 3 plus min that I measured for. Should be fine to leave the components covered in the housing.

Quick note: The typical material used for the headlight housing is good to 300+ F and the wire insulation at least 210+F (for the cheap stuff).

https://www.mouser.com/applications/lighting-derating/

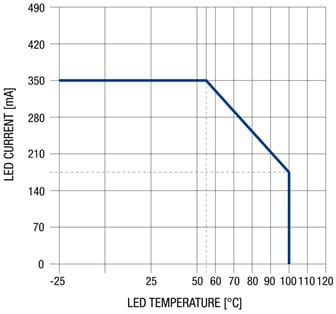

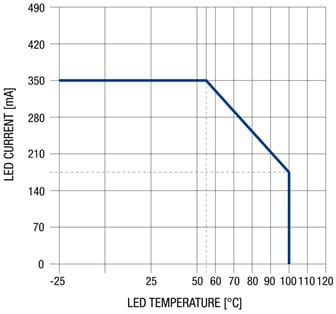

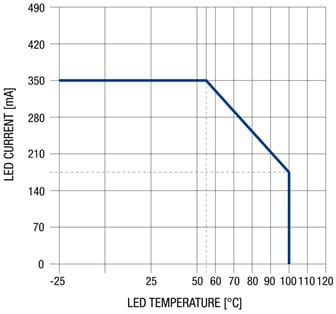

That's way too hot for them not to dim, we're not talking about the material melting, LED brightness/power draw drops dramatically at temps past 50 centigrade/122 Fahrenheit according to this chart I found real quick, there is other sources out there too.

https://www.mouser.com/applications/lighting-derating/

https://www.mouser.com/applications/lighting-derating/

I did not find a data sheet for the Exact LED chip in the Hikari but here are two examples of Phillips LEDs. You can see that the relative light output vs pad temperature there is a very small change between 65 and 80C. Also since the measurement was taken at several points in time with the back cover off the last temp taken of the bulb heat sink was fairly representative of the nominal temp on the system in the open air environment of the engine bay. Essentially leaving the cap off did little to reduce this temperature.

Attachments

-

720.3 KB Views: 15

-

437.8 KB Views: 14

-

104.7 KB Views: 8

-

110.1 KB Views: 11

Thread Starter

#167

Thread Starter

#167

This in not the correct plot to evaluate temp vs light output. First this to consider the local temp is ~65C as the measured in the engine bay. This sets on lowest possible temperature. The bulb heat sink temp was measured at ~79C.

I did not find a data sheet for the Exact LED chip in the Hikari but here are two examples of Phillips LEDs:

I did not find a data sheet for the Exact LED chip in the Hikari but here are two examples of Phillips LEDs:

Sent from my LG-H932 using Tapatalk

They are referencing the environmental temp and not the bulb heat sink temp. Without external air ducting 65C is the best it will get which is in spec.

Keep in mind Environmental temp(working temp) is highly dependent on the cooling design. The higher quality systems will have better materials and bearings (if they have fans) yielding higher working temps or at the very least improved temperature stability.

Keep in mind Environmental temp(working temp) is highly dependent on the cooling design. The higher quality systems will have better materials and bearings (if they have fans) yielding higher working temps or at the very least improved temperature stability.

Thread Starter

#169

Thread Starter

#169

They are referencing the environmental temp and not the bulb heat sink temp. Without external air ducting 65C is the best it will get which is in spec.

Keep in mind Environmental temp(working temp) is highly dependent on the cooling design. The higher quality systems will have better materials and bearings (if they have fans) yielding higher working temps or at the very least improved temperature stability.

Keep in mind Environmental temp(working temp) is highly dependent on the cooling design. The higher quality systems will have better materials and bearings (if they have fans) yielding higher working temps or at the very least improved temperature stability.

Increasing the thermal mass and surface area is your best bet to reduce the temperature in the bulb. The challenge is obtaining a bond with sufficient thermal transfer and doing this without negatively impacting the existing thermal management system.

It’s hard to say whether the closed assembly is better/worse than the open back without CFD modeling both systems. The closed system may have benefits by not loosing the potential cooling effects of the outside air cooling the lense thus having a larger cooling effect on the small contained volume in the headlight assembly.

I’m curious how you are going to measure your results of using the different caps and added heat sinking material? I think the most insightful testing would be to measure the lumen output and temperatures in the various configurations. Without a measurement of the optical output we really don’t know how the LED is changing with temperature.

It’s hard to say whether the closed assembly is better/worse than the open back without CFD modeling both systems. The closed system may have benefits by not loosing the potential cooling effects of the outside air cooling the lense thus having a larger cooling effect on the small contained volume in the headlight assembly.

I’m curious how you are going to measure your results of using the different caps and added heat sinking material? I think the most insightful testing would be to measure the lumen output and temperatures in the various configurations. Without a measurement of the optical output we really don’t know how the LED is changing with temperature.

Thread Starter

#171

Thread Starter

#171

So I decided to put my money where my mouth was and finally ordered some rear covers.... I went with the top rated ones that are $10 on Amazon and more of a universal type where you trim away the excess as it's "accordion" style. I'll post some pics when I install this weekend.

https://smile.amazon.com/dp/B076Q9D52Z/

https://smile.amazon.com/dp/B076Q9D52Z/

Thread Starter

#172

Thread Starter

#172

Increasing the thermal mass and surface area is your best bet to reduce the temperature in the bulb. The challenge is obtaining a bond with sufficient thermal transfer and doing this without negatively impacting the existing thermal management system.

It’s hard to say whether the closed assembly is better/worse than the open back without CFD modeling both systems. The closed system may have benefits by not loosing the potential cooling effects of the outside air cooling the lense thus having a larger cooling effect on the small contained volume in the headlight assembly.

I’m curious how you are going to measure your results of using the different caps and added heat sinking material? I think the most insightful testing would be to measure the lumen output and temperatures in the various configurations. Without a measurement of the optical output we really don’t know how the LED is changing with temperature.

It’s hard to say whether the closed assembly is better/worse than the open back without CFD modeling both systems. The closed system may have benefits by not loosing the potential cooling effects of the outside air cooling the lense thus having a larger cooling effect on the small contained volume in the headlight assembly.

I’m curious how you are going to measure your results of using the different caps and added heat sinking material? I think the most insightful testing would be to measure the lumen output and temperatures in the various configurations. Without a measurement of the optical output we really don’t know how the LED is changing with temperature.

I am going to try the cree chipped hikari the cheaper ones for my brights and see how they are/differ from the hikari led with phillips chips. ill post a pic up once they are installed.![Wrenchin [wrenchin] [wrenchin]](/images/smilies/icon_smile_wrenchin.gif)

![Wrenchin [wrenchin] [wrenchin]](/images/smilies/icon_smile_wrenchin.gif)

https://sellercentral.amazon.com/nm...JPkBVHg&n=1&u=aHR0cHM6Ly9hbXpuLnRvLzJNV3A3Vko

https://sellercentral.amazon.com/nm...JPkBVHg&n=1&u=aHR0cHM6Ly9hbXpuLnRvLzJNV3A3Vko

Thread Starter

#175

Thread Starter

#175

can post up a pic on the fitment of the covers i was about to put some holes in the stockers and call it a day but i saw you linked the nice ones just wondering if you got around to it.

Are these bulbs still recommended? Looking for some better output for night driving.

https://www.amazon.com/Headlight-Co...079KB7QX3/ref=cm_cr_arp_d_product_top?ie=UTF8

https://www.amazon.com/Headlight-Co...079KB7QX3/ref=cm_cr_arp_d_product_top?ie=UTF8

Thread Starter

#177

Thread Starter

#177

Are these bulbs still recommended? Looking for some better output for night driving.

https://www.amazon.com/Headlight-Co...079KB7QX3/ref=cm_cr_arp_d_product_top?ie=UTF8

https://www.amazon.com/Headlight-Co...079KB7QX3/ref=cm_cr_arp_d_product_top?ie=UTF8

Of course the Amazon guide to fitting isn't always right but it does say they will fit.... they very well may be short enough to clear the back housing, if you have Prime they would be easy to return if they don't fit, otherwise they DO look worthy of trying out.

Similar threads

-

-

-

-

-

Does anyone here use the State Farm Drive Safe and Save app?

- Started by pixelzombie

- Replies: 13

-

-

Goo gone safe on dashboard?

- Started by BlackBeanAndRice

- Replies: 4

-

Should I tune for 91 and just run 93 for an extra margin of safety?

- Started by SwissLime

- Replies: 36

-

-