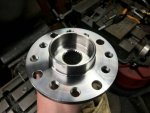

I created this thread to promote an important discussion that was brought up. Some of you may be aware, but I converted my wheel hubs to 4x100, and did so in a manner not typical of other Fiesta ST owners.

My new hubs were drilled by Alex, as many of yours are. The difference lies where I had him drill two extra sets of holes, one @ 4x100 and another @ 4x108. I also had him thread these holes to M12x1.5 and am using threaded studs from Turner motosports, found here.

--------------

Question:

Very good question. Of course the studs won't break, right... but the threaded hubs we should think about? Hmm. I'm not an engineer, but I do have engineer friends and they assured me this conversion is more than fine, particularly that there are no real tensile loads that will be applied to the studs or threaded holes that will cause a catastrophic fail, other than maybe in a really bad wreck. And in really bad wrecks, we've all seen the wheels fall off. Another thing to consider is our use of hubcentric rings... which squarely put load on the vehicle hub and not the wheel studs, and also these parts being steel. I do not know what type of steel our hubs are constructed of, unfortunately. Maybe an engineer can chime in.

Experience:

That said, I have personally used threaded studs (Bimmec, Turner, ARP, and MSI) on various Volkswagens and Audis, albeit all of which makes and models came from factory with threaded hubs, meaning that the hubs were "engineered" with this for the purpose of using wheel bolts, just like your E36. I would guess it to be the case, but I cannot confirm the thickness of the VW and Audi hubs. I want to say that my VW hubs were no more thicker than my Fiesta hubs, used the same studs, and were likely made of the same exact material although I can't really confirm the last bit. The Audi hubs were hefty I do remember that, as my cars were AWD monsters that weighed over 2 tonnes. You bring up a good point that does spark some curiosity though, because our cars were not "engineered" purposely for this. Let's examination...

Data:

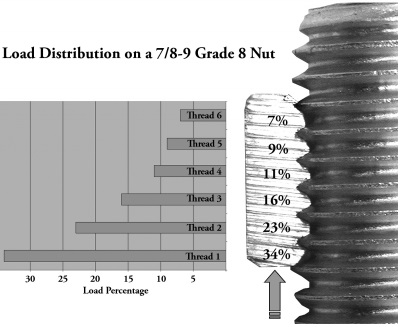

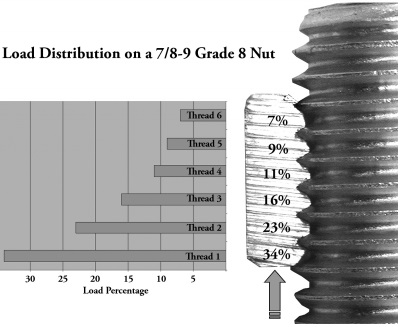

I could have used any thread pitch, but I kept our factory M12x1.5. According to the internets, that is 16.9 threads per inch (TPI).

I happen to have the original hubs sitting right here next to me. They measure at exactly 9mm thick. 1" = 25.4mm.

25.4 / 9 = 2.8

16.9 (TPI) / 2.8 = 6 threads of engagement.

Popular opinion:

My engineer friends tell me that 6 threads engaged is a safety factor of 2. So with all that, and I never really thought about how safe it would be other than they are steel studs threaded into a steel hub and should be plenty safe having 6 full threads of engagement, so still I know that I am kinda the guinea pig here. With the studs, I've already hit curbs all around Laguna Seca, and have a track day at Sonoma in two weeks, we'll see how they do.

I also found this chart on the internet too. Maybe there's an engineer or two on the forums that can chime in to confirm. [emoji481]

Let's chat!

My new hubs were drilled by Alex, as many of yours are. The difference lies where I had him drill two extra sets of holes, one @ 4x100 and another @ 4x108. I also had him thread these holes to M12x1.5 and am using threaded studs from Turner motosports, found here.

--------------

Question:

What's the engagement on the threads there? Not sure what kind of load those threads would see, maybe it's not a big deal but for some reason the conversion makes me nervous. Have you seen this conversion on other hubs? Did some google-ing and didn't find much.

Experience:

That said, I have personally used threaded studs (Bimmec, Turner, ARP, and MSI) on various Volkswagens and Audis, albeit all of which makes and models came from factory with threaded hubs, meaning that the hubs were "engineered" with this for the purpose of using wheel bolts, just like your E36. I would guess it to be the case, but I cannot confirm the thickness of the VW and Audi hubs. I want to say that my VW hubs were no more thicker than my Fiesta hubs, used the same studs, and were likely made of the same exact material although I can't really confirm the last bit. The Audi hubs were hefty I do remember that, as my cars were AWD monsters that weighed over 2 tonnes. You bring up a good point that does spark some curiosity though, because our cars were not "engineered" purposely for this. Let's examination...

Data:

I could have used any thread pitch, but I kept our factory M12x1.5. According to the internets, that is 16.9 threads per inch (TPI).

I happen to have the original hubs sitting right here next to me. They measure at exactly 9mm thick. 1" = 25.4mm.

25.4 / 9 = 2.8

16.9 (TPI) / 2.8 = 6 threads of engagement.

Popular opinion:

My engineer friends tell me that 6 threads engaged is a safety factor of 2. So with all that, and I never really thought about how safe it would be other than they are steel studs threaded into a steel hub and should be plenty safe having 6 full threads of engagement, so still I know that I am kinda the guinea pig here. With the studs, I've already hit curbs all around Laguna Seca, and have a track day at Sonoma in two weeks, we'll see how they do.

I also found this chart on the internet too. Maybe there's an engineer or two on the forums that can chime in to confirm. [emoji481]

Let's chat!

Last edited:

![Wink [wink] [wink]](/images/smilies/wink.gif) ).

).