Do you guys have your favorite blowoff valve? Have one sitting on the shelf but haven't installed on because you're not big turbo or have upgraded charge pipes? Well here's my easy solution to all of that.

1: pick your BOV- I choose a Knockoff Tial BOV for $45 on eBay with a 10psi Spring

2: gather these parts- BOV, 1.5"-2" pipe-I used a pvc adapter-, 4" of 2" tubing- I used mine from the pipe on the end of the resonator on the charge pipe from the turbo-, 1.5" hose clamp, 2-2" hose clamps, vacuum line, 1 zip tie- long enough for your mounting-, *if you have a Boomba throttle body spacer, get a 1/8 npt to 1/4 nipple, or get a vacuum source plate http://www.atpturbo.com/mm5/merchan...tp&Product_Code=ATP-FIE-005&Category_Code=FIE from atp*

3: remove your sound symposer and/or your delete kit

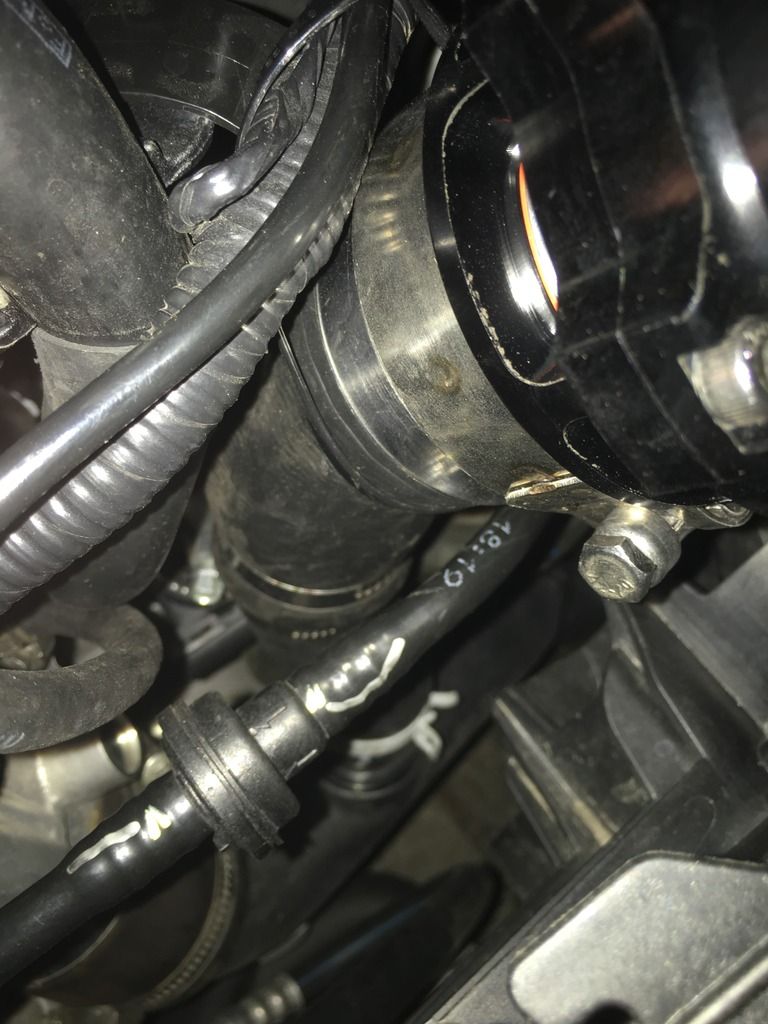

4: leave the 1.5" pipe from the charge pipe and add your 1.5-2 adapter to the 1.5" tube

5: get your BOV- mine had a weld-on piece with a VBand that I got in the 2" pipe and put a 1 of your 2" hose clamps on then assembled the vband to the BOV

6: attach the 2" piping to the 2" side of your adapter

7: keep hose clamps loose and use the bends in the factory symposer piping to adjust the mounting location.

8: remove the plug in your Boomba throttle body spacer and install the nipple- or add your vacuum block

9: route your vacuum hose from your vacuum source to your BOV

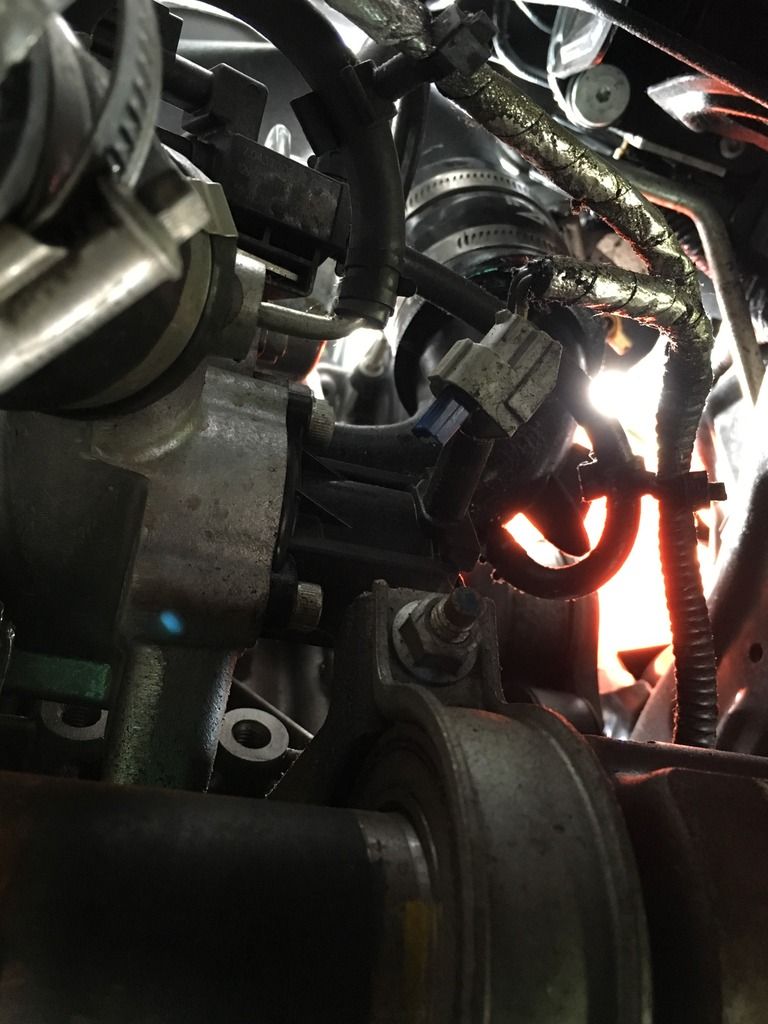

10: jack the passenger side of the car high enough to crawl under, place a jack under the car and make sure the ebrake is on and the car is in gear.

11: crawl under and search for the factory recirculating valve and the plug that goes to it- grey plug-

12: lower car and then wrap a zip tie around the mounting of the BOV and wrap it around a wire bundle with a mount on the manifold

Now if you have a tuner- ask them to disable P0035- it's a recirc code for not being plugged in, if you aren't tuned, no worries either. Ran mine for a day without any problems before my tuner could get me that tune revision.

And there you go. Things you'll notice, my boost curve was smoother on Vdyno- how accurate that really is you tell me but the curve was smoother. Recirc noise at part throttle is gone!! You'll still hear intake noise, but the constant whirling is gone and so much better to listen to. Now my knock off tial doesn't produce the greatest sound, it holds 26.51psi and works the way it should. Good luck and videos will be posted shortly.